Free Machine Vision Evaluations at RR Floody Machine Vision Lab

August 12, 2019

Cognex In-Sight 2000 Mini Vision Sensors

August 12, 2019Power of In-Sight with the ease-of-use and affordability of a vision sensor.

In-Sight® 2000 Mini series vision sensors combine the power of an In-Sight vision system with the simplicity and affordability of a vision sensor.

In-Sight® 2000 Mini series vision sensors combine the power of an In-Sight vision system with the simplicity and affordability of a vision sensor.- High speed liquid lens provide maximum application coverage

- Proven In-Sight tools ensure reliable inspection performance in a single setup environment

- Field interchangeable lighting adapts to virtually any production line environment without the need for external lights

- Miniature, modular body design with in-line or right-angle mounting provides maximum flexibility in tight spaces

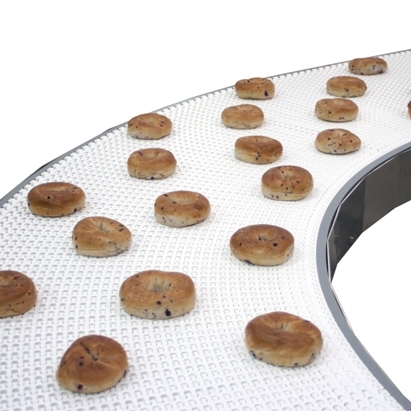

SANITARY VS. STAINLESS STEEL CONVEYORS

May 23, 2019By John Kuhnz

Vice President, Engineered Solutions Group, Dorner Mfg. – Read Original Article

There are many factors that drive food processors to upgrade their conveyor systems to a more sanitary platform. Leading the charge is the Food Safety Modernization Act (FSMA), which takes a more proactive approach toward food safety by adding safeguards to try and prevent contamination or problems from occurring within the nation’s food supply in the first place. Besides the FSMA, companies cannot afford to have a contamination outbreak traced back to poor sanitary designs in their equipment. The risks to their reputation and to their customers’ well-being are too great.

So as companies scrutinize how to improve their food processing practices and stay ahead of the FSMA, installing new sanitary conveyors is often one of the conclusions they arrive at. That’s a sound decision because conveyors are in direct contact with food, especially on the processing side. These conveyors need to be built with strong sanitary attributes to eliminate any chance of contamination. However, not all “sanitary” conveyors are built the same. Let’s take a look at some of the engineering and design differences that make a conveyor a truly sanitary platform.

Is stainless steel truly sanitary?

A common misconception is that all stainless steel conveyors are sanitary. When the FSMA was announced a few years ago, many companies went out and purchased stainless steel conveyors thinking they were going to get a high level of sanitary protection. While that purchase provided them with a stainless steel conveyor, they might not have received a truly sanitary conveyor…and there’s a big difference between the two. Here’s why:

Stainless steel is certainly the right material to use in applications that call for regular washings with light chemical cleaning agents. A basic stainless steel conveyor can be washed throughout the day as needed, depending on how it’s built, but it’s not necessarily sanitized. That’s because sanitizing a conveyor involves an entirely different process than simply washing it down, and much of achieving a sanitized conveyor depends on the way it was initially designed.

What makes a true sanitary conveyor?

The goal of a sanitary conveyor is to, as best as possible, eliminate any chance of contamination. By their very nature, conveyors are an excellent source of contamination; especially on the processing side where raw food and ingredients are being moved. A sanitary conveyor works to eradicate those areas where contamination can happen…and that starts with the design of the frame.

A true sanitary conveyor gives the user full easy access to all areas of the conveyor for cleaning. By being able to reach every part of the conveyor with water, soap or other cleaning agents, there’s no chance of product collecting and growing into bacteria.

Additionally, a sanitary conveyor removes harbor points, blind spots and flat level surfaces within the frame structure, and replaces them with rounded cross members preventing food and water from accumulating. This design element is important because it doesn’t take long for components within the conveyor, like the motor, to begin heating up collected food particles and speeding up contamination. Also, the overall openness of the frame is designed so that any product that falls off the belt will land either in a catch pan below or on the floor; nothing gets trapped within the frame.

Other hygienic designs common in sanitary conveyors are the removals of plate-on-plate manufacturing on the frame. Often, these plate-on-plate designs involve sections of the frame bolted together with fasteners, and do not allow the user to take them apart for cleaning. This leads to food particles collecting in the crevices and spreading bacteria. Sanitary conveyors don’t have this type of manufacturing design. Rather, fasteners, which are harbor points for contamination, are removed from the conveyor’s food zone and replaced with welds where necessary – again all aimed at making the conveyor as hygienic as possible. These proactive design elements of the conveyor mirror the philosophy of the FSMA in that both attempt to eliminate the sources of contamination before they have a chance to occur.

Different levels of sanitary

Also important to keep in mind when researching sanitary platforms is where in the plant the conveyor is located. For applications more downstream in processing where the conveyor is moving sealed and packaged food, the conveyor might not need to be as hygienic as those carrying raw food and ingredients. These conveyors often accumulate corrugated dust from the cardboard packaging, and that can be cleaned by washing or simply wiping down the conveyor. This conveyor is still sanitary in design, but for this application the more robust sanitary platform isn’t commonly required.

Education is the key in selecting the right sanitary conveyor

A well-built sanitary conveyor will have these types of hygienic designs engineered into it. So the questions to ask when researching a sanitary conveyor system are:

- Where is the conveyor going to be located in your plant?

- How accessible is the conveyor to take it apart?

- Is it easy to disassemble and can it be performed by one person with no tools?

- Can you effectively wash and sanitize the conveyor because it’s designed properly?

- Is the conveyor truly going to meet your sanitary expectations?

Just because a conveyor is stainless steel doesn’t necessarily mean it’s engineered with these hygienic attributes. And that’s really the crux of the whole sanitary vs. stainless steel comparison; a lot more thought process from an engineering standpoint has gone into the sanitary conveyor to make it truly a hygienic platform.

The sanitary designs were considered upfront during the designing phase so that the conveyor will be much more productive for you once installed and operating in your facility. Understanding the different levels of sanitary standards available in conveyors will go a long way toward giving you peace of mind in knowing you’ve purchasing the right sanitary conveyor for your application.

John Kuhnz is the vice president of the Engineered Solutions Group, at Dorner Manufacturing. He can be reached at 262-369-1332 or john.kuhnz@dorner.com

Dorner Mfg. Corp. 2016. All Rights Reserved.

6 Rules for Successfully Applying Machine Vision

May 20, 2019

|

MiR1000 Mobile Industrial Robots

May 16, 2019Automate Transport Tasks

The new MiR1000 ™ is the most robust robot that Mobile Industrial Robots offers to date, with a payload of 1000 kg (2,200 lbs). You are able to optimize your pallet transportation: MiR1000 picks up, transports and delivers pallets autonomously with the MiR1000 pallet lifts, and ensures a smooth, safe, and efficient transportation of your pallets.

™ is the most robust robot that Mobile Industrial Robots offers to date, with a payload of 1000 kg (2,200 lbs). You are able to optimize your pallet transportation: MiR1000 picks up, transports and delivers pallets autonomously with the MiR1000 pallet lifts, and ensures a smooth, safe, and efficient transportation of your pallets.

MiR1000 automatically navigates around obstacle, and is able to re-route to avoid stopping or delaying the delivery of materials. MiR1000 does not need to be manned, so it optimizes the transportation of pallets and frees up employees for more valuable tasks.

MiR1000 is controlled via smartphone, tablet or computer using the intuitive MiR Robot Interface, and it can be programmed without prior programming experience.

Cognex In-Sight 9000 12MP Vision System

February 14, 2019Single camera solution to multi-camera applications

The In-Sight 9000 series offers Cognex’s first rugged, ultra-high-resolution, standalone vision systems. With its ability to acquire and process exceptionally detailed images, the In-Sight 9000 delivers high accuracy part location, measurement, and inspection over a large area—even when mounted at longer distances. Line scan and area scan image acquisition options are available for imaging continuously moving or stationary objects.

The In-Sight 9000 series offers Cognex’s first rugged, ultra-high-resolution, standalone vision systems. With its ability to acquire and process exceptionally detailed images, the In-Sight 9000 delivers high accuracy part location, measurement, and inspection over a large area—even when mounted at longer distances. Line scan and area scan image acquisition options are available for imaging continuously moving or stationary objects.

Stand-out features include:

- Area scan and line scan image options for imaging continuously moving or stationary objects

- Cognex’s full suite of vision tools

- Easy configurability through the In-Sight EasyBuilder interface

- 12MP (area scan) and 32MP (line scan) image acquisition

STAY AHEAD OF THE GAME WITH UNIVERSAL ROBOTS E-SERIES

December 26, 2018With the e-Series you can unpack, mount and program your cobot in less than an hour with no special electrical requirements.

Built with the future in mind, the e-Series is designed to grow in capability alongside your business, a spring board to improved product quality and productivity, so you will always be able to stay ahead of competition. Equipped with intuitive programming, versatile use and an almost endless list of opportunities for add-ons, the e-Series is able to complement production regardless of your industry, company size or product nature.

- 0.03mm repeatability on UR3e/UR5e, UR10e 0.05mm

- Built in Force/Torque sensor

- New Control Box and Teach Pendant Design

- New programming software that is even easier

Does a Flex Feeding System Make Sense for You?

November 8, 2018Tech Brief:

Flexible Part Feeding or flex feeding refers to a process used to feed or load parts into a manufacturing process. A flex feeding system is comprised of a flexible feeder (to feed the part), a vision system (to help the robot locate part) and a robot (to pick and place the part). The main advantage of a flex feeding system is that it allows for different parts to be fed into the same system with little to no effort on the operator’s part. With the availability of low cost robots and the variety of high performance flex feeders, flex feeding systems are hot right now but they might not be right for everyone.

Flexible Part Feeding or flex feeding refers to a process used to feed or load parts into a manufacturing process. A flex feeding system is comprised of a flexible feeder (to feed the part), a vision system (to help the robot locate part) and a robot (to pick and place the part). The main advantage of a flex feeding system is that it allows for different parts to be fed into the same system with little to no effort on the operator’s part. With the availability of low cost robots and the variety of high performance flex feeders, flex feeding systems are hot right now but they might not be right for everyone.

Read this article for the three-step evaluation process used to determine whether a flex feeding solution makes sense for your application.

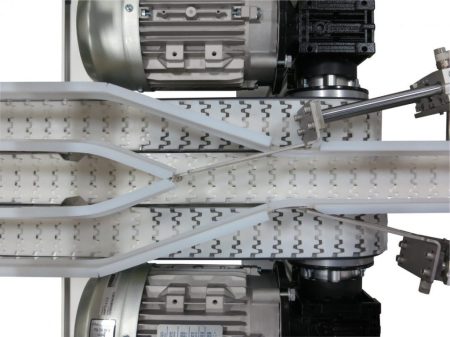

5 Unique Conveyor Solutions to Merge Product

September 12, 2018

Merging Conveyors are used to consolidate the flow of product from multiple infeed lines. Typically, these systems will merge the product into a single stream on one conveyor for the next phase in the production process.

There are many ways to merge product, such as: diverters and gates, product pushers, lane guiding, ARB Conveyors and more.

These systems are created to ensure facilities are running efficiently and eliminating bottlenecks while avoiding product pile up or overflow.

Choosing the right type of merge system depends on the application and characteristics of the product that it is created for. Each product is different and Dorner’s custom merge conveyors are engineered to your specific needs.

Here are some examples of solutions we’ve created in the past:

Heavy Duty Product Pusher

This system is merging two infeed lines using a product pusher. Baskets carrying product weighing up to 500 lbs are transferred onto the center conveyor in front of the pusher from either line.

Once the photo eyes confirm the basket is in the correct position, the pusher is activated and transfers the product onto the takeaway conveyor (not pictured).

Powered Side Guide Merge

While standard UHMW guides can often be used for simple 2-to-1 merges, some applications can benefit from a powered side guide. These can be useful in situations such as: heavy product that needs assistance over the side transfer, delicate product that you don’t want rubbing on the guide, and precision applications where you want better speed control through the merge.

The powered side guide can also be used to pull a gap between products.

Pneumatic Gate Merge

For this application, empty bottles were traveling down two different infeed lines and needed to be merged onto a single line. Pneumatic gates at the point of the merge can open or close, allowing one line through while bottles are able to accumulate behind the closed gate.

Pneumatic Product Squeezer

This application is very similar to the previous merge, but instead of gates, the system uses pneumatic squeezers.

When one of the infeed conveyor flows needs to be stopped, the squeezer activates and holds the rolls of paper in place. This allows rolls on that side to accumulate until released.

4-to-1 Merge

Using our sanitary AquaPruf conveyors, we designed this 4-to-1 packaging merge with servo motors and photo eyes to maintain fast and consistent product throughput. Since this system was made for a food application, the stainless steel conveyors are completely washdown for sanitation and food safety.

Tech Brief: 6 Rules for Successfully Applying Machine Vision

August 23, 2018 New vision applications at RR Floody commence with a documented application evaluation process. This process is based on decades of machine vision experience, and we truly feel it is not only the correct way to approach machine vision; but the only way.

New vision applications at RR Floody commence with a documented application evaluation process. This process is based on decades of machine vision experience, and we truly feel it is not only the correct way to approach machine vision; but the only way.

Rule #1. Good data in, equals good data out . . .

Rule #2. Make certain you are programming from a “Golden Image”. . .

Rule #3. Accurately name your inspection tools and machine vision components. . .

Rule #4 Check your work . . .

Rule #5 When in doubt, consult an expert . . . (RR Floody

Rule #6 No Fear! . . .

New vision applications at RR Floody commence with a documented application evaluation process that consist of

New vision applications at RR Floody commence with a documented application evaluation process that consist of